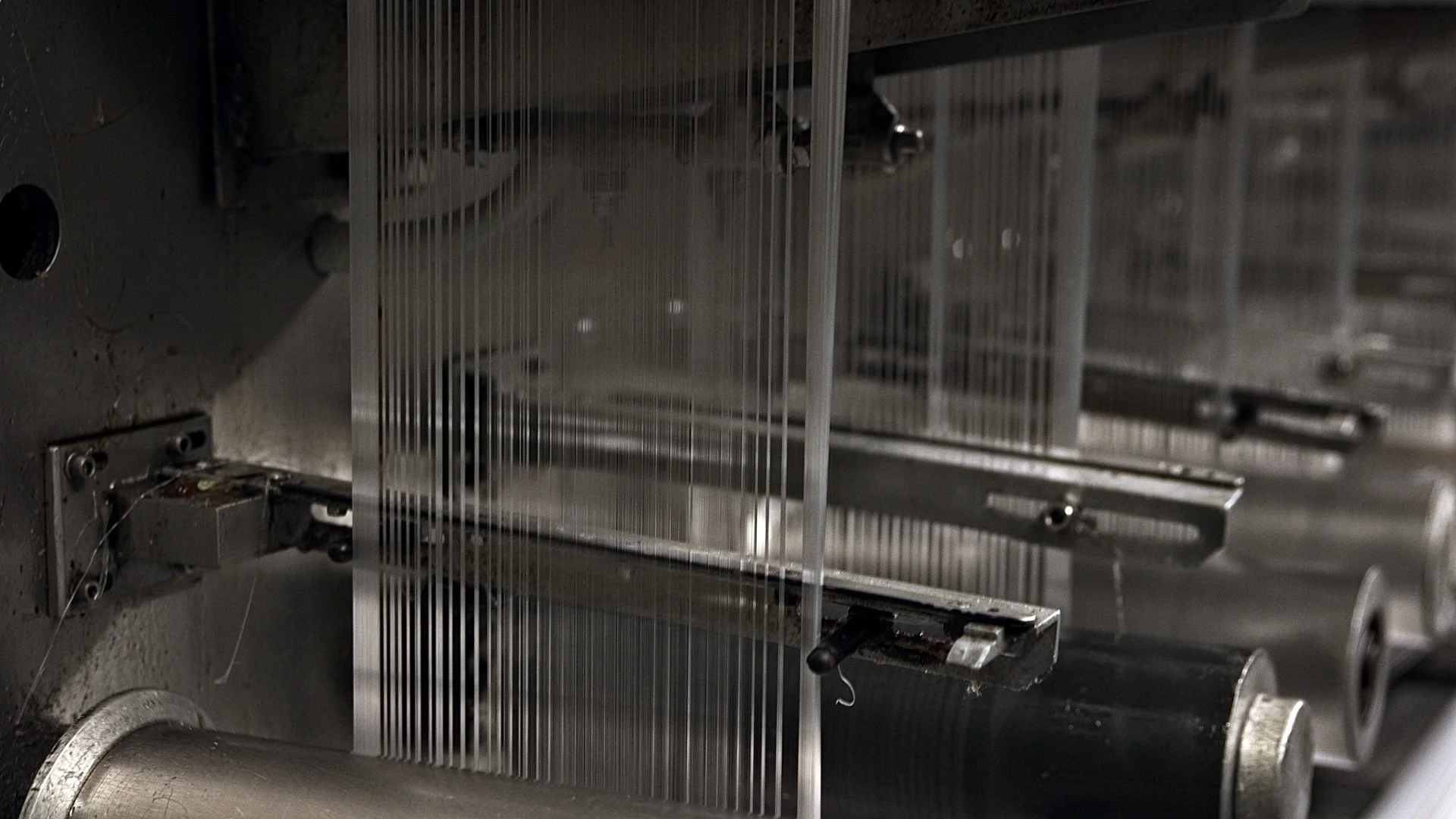

Our customers rely on the exceptional standards of high-quality staple fiber

Drake's solution-dyed staple fiber sets the benchmark across the globe for quality and consistency. By utilizing our unique state-of-the-art coloration system, we can ensure unparalleled consistency for the most exacting of applications.

Polypropylene’s inherent qualities of being lightweight and hydrophobic make it the fiber of choice for many applications. Our polypropylene staple fibers are designed to meet our customers' most meticulous needs and specifications for their end product.

Our services

Production

Drake has six staple lines that can process between 2 DPF and 110 DPF Polypropylene staple fiber in custom colors with cut lengths of 25mm to 150mm.

These six staple lines can produce 65 million lbs. a year of staple fiber for a multitude of spun and non-woven markets.

Precision Color

Color is what we do best. We are the only staple fiber manufacturer in the U.S. that can customize any automotive textile specifications. We also work with designers from home furnishings, floor coverings and other highly specialized markets to custom match products without compromising function.

Customization

Our wide range of capabilities in denier, cut length and high tenacity staple fiber gives our customers maximum flexibility for the design and durability of their product. Additional features include biodegradable and low shrink capabilities. Our team will collaborate with yours to create custom color and additive options for a truly unique result.

Flexibility

Our products are made to order for you. This allows Drake to be nimble and reactive to our customers' needs and timelines. We do not keep a generic stock of fibers in our facility. What's in our warehouse ships within 24 hours. Drake is on standby to produce what you need, when you need it.

“We work together with our clients to create the product they need - even if it’s something completely new.”

— Chris Jackson, Yarn Plant Manager